After years of solid and rapid development, Enbon has grown into one of the most professional and influential enterprises in China. indoor led video wall We have been investing a lot in the product R&D, which turns out to be effective that we have developed indoor led video wall. Relying on our innovative and hard-working staff, we guarantee that we offer customers the best products, the most favorable prices, and the most comprehensive services as well. Welcome to contact us if you have any questions.The product is lightweight, which means it greatly saves transportation cost and brings much convenience for people.

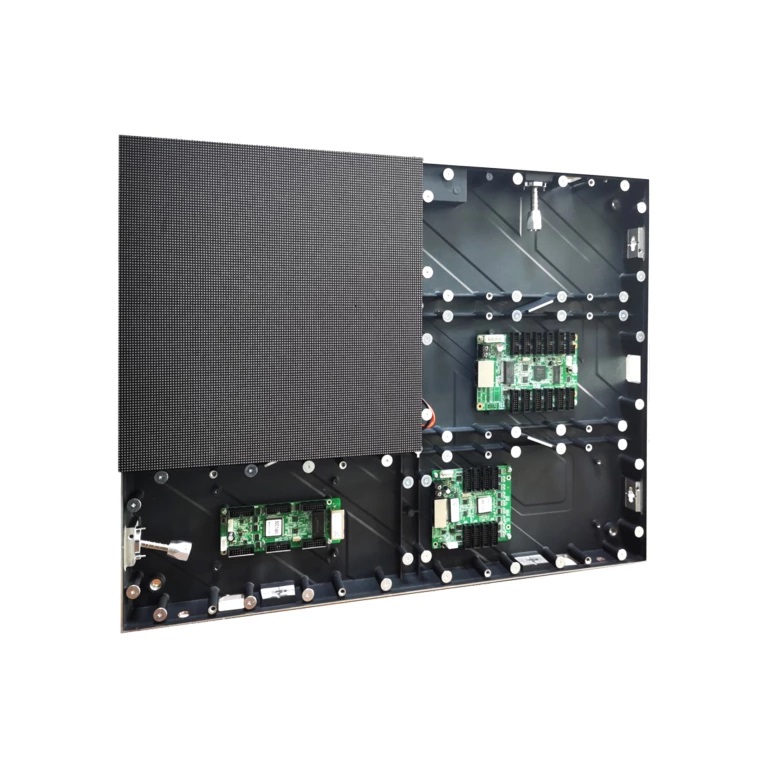

Enbon FS-Plus series is a LED display screen uses for indoor staging, exhibitions, shopping malls and other social events. The weight of the box is 40% lighter than the traditional iron box, which saves a lot of costs. Anti-knock design to avoid damage to the module, reducing maintenance and improve work efficiency. High brightness and high contrast maintain the suction cup tool before use. The iron plate is installed on the back of the module and is easy to disassemble and assemble. Current sharing gives consistent power to panel, in case of any panel power supply failure. With bringhtness control that you could adjust brightness degree to the resultt you want.

┃ Product Parameters

Pixel Pitch | 1.25, 1.53, 1.86, 2.5, 3 |

LED lamp | SMD1010(P1.25) SMD1515(P1.53, P1.86) SMD2020(P2.5, P3) |

Brightness | 500nits(P1.25) 600nits(P1.53) 800nits(P1.86) 900nits(P2.5, P3) |

Module pixel | 256*128dots(P1.25) 208*104dots(P1.53) 172*86dots(P1.86) 128*64dots(P2.5) 104*52dots(P3) |

Cabinet pixel | 534*400dots(P1.25) 405*304dots(P1.53) 341*256dots(P1.86) 256*192dots(P2.5) 213*160dots(P3) |

Module size | 320*160mm (P1.25, P1.53, P1.86, P2.5, P3) |

Cabinet size | 640*480*85mm(P1.25, P1.53, P1.86, P2.5, P3) |

Module weight | 0.5kg(P1.25, P1.53, P1.86, P2.5, P3) |

Cabinet Weight | 5.5kg(P1.25, P1.53, P1.86, P2.5, P3) |

Work humidity | 10% ~ 90% |

Work temperature | ﹣20 ~﹢65℃ |

Operating system | AV, S-Video, VGA, DVI, YPbPr, HDMI, SDI |

Brightness control | 256 level |

Max Power | 500 w/sqm(P1.25, P1.53, P1.86, P2.5, P3) |

| Average Power | 160 w/sqm(P1.25, P1.53, P1.86) 200 w/sqm(P2.5, P3) |

| IP rating | IP40 |

| Control way | Synchronous/Asynchronous |

Viewing Angle | ≥160° (horizontal), ≥160° (vertical) |

| Density | 695556dots/m2(P1.25) 401111dots/m2(P1.53) 284444dots/m2(P1.86) 160000dots/m2(P2.5) 111111dots/m2(P3) |

Cabinet Materiel | Die-casting Aluminum |

┃ Product Display

┃ Feedback

┃ FAQ

Q :What method do you use to improve luminance and color uniformity

A: The most important thing is to find out is what your screen manufacturer does to fix the inherent non-uniformity issues found in all LEDs. The method that yields the best results is the PWM correction method, and it often produces a screen that is cheaper than extreme binning methods, because the screen manufacturer does not need to purchase such tight binning lots from the LED manufacturers in order to achieve uniformity. Also, it enables the user to recalibrate the screen as the LEDs become dimmer over the course of several years.

Q: Are correction coefficients used for each pixel or only for each module?

A: For best results, correction coefficients should be provided for each pixel. Correction coefficients for the module can reduce or eliminate the patchwork quilt effect that shows modules with different brightness and color, but it cannot completely remove the boundary differences between different modules and will do nothing to eliminate the dirty window effect caused by pixel-to-pixel uniformity differences

Q: How many correction coefficients are used for each pixel?

A: It is possible to produce correction only for luminance and white point. A screen of this type will use 3x1 correction coefficients (3 coefficients for each pixel). A full color corrected screen will use 3x3 coefficients (9 coefficients for each pixel).

Q; Are the PWM coefficients stored in the modules in addition to storing them in the video controller?

A: The coefficients need to be stored in the video controller in order to perform the video signal processing; however, it is also very convenient to store them in a type of flash memory on the module. This not only provides a backup for the coefficients, but it also enables the module to automatically update the coefficient database in the video controller when it is moved or replaced.